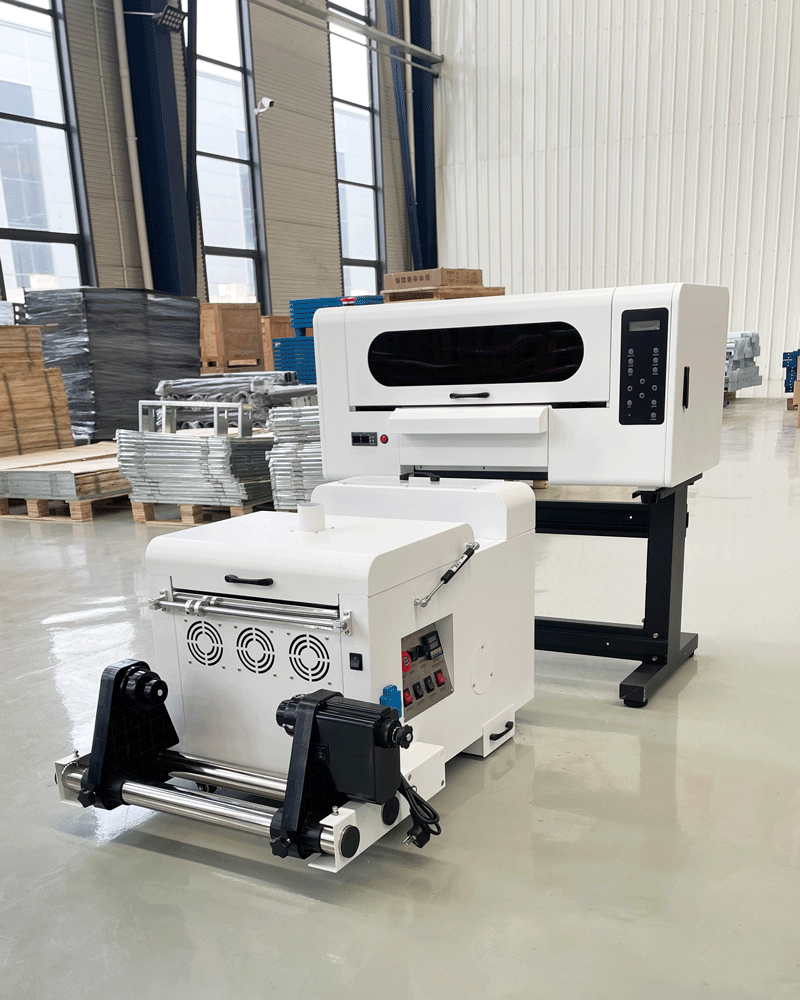

Shaker/dryer 100*50*58cm

Production equipment#10001

Article: Shaker/dryer

Categories: DTF Printer, Equipment, Materials

Tags: DTF, Powder Shaker, Printing, Dryer, Powder Dispensing Device

The "Shaker" automatically applies powder and distributes it evenly after the DTF printer prints your desired design. The machine is equipped with a heat emission system that precisely melts the correct amount of adhesive onto the design.

The machine has a built-in screen that allows you to control the temperature. It also features an automatic mode that includes film winding, even powder distribution on the wet surface, “shaking,” and drying. Additionally, if needed, you can activate a cooling function that further simplifies the printing process.

The "Shaker" also stands out for its mobility, thanks to the wheels, making it easier to move.

This particular model is designed for 30 cm wide film.

DTF (Direct to Film) technology is a method of printing directly onto the film. In this process, the DTF printing machine applies a CMYK print, followed by a white covering layer. The printed material is then passed through a device known as a shaker. Its main function is to distribute a special powder onto the ink. Since the ink is still wet at this stage, the powder adheres easily to the final white layer of the ink. The powdered print is then placed in an oven, where the powder melts and the ink dries. After the oven, the film is automatically wound onto a roll. Once this process is complete, the print can be transferred directly onto textiles.

To transfer the print onto fabric, place the fabric in a heat press, lay the printed material on top, and press for a few seconds.

Shaker/dryer